TECHNOLOGICAL DESIGN OF A WAREHOUSE LOGISTICS

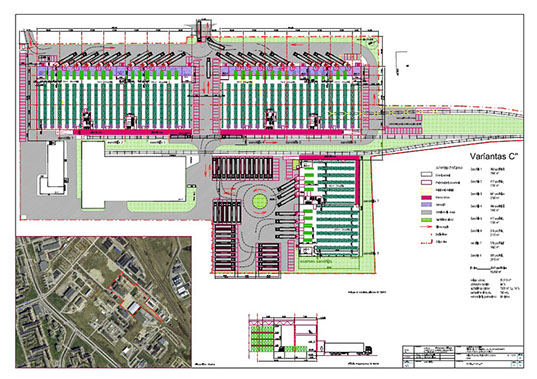

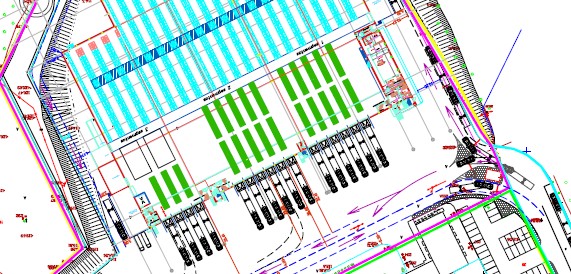

We help our customers to design new warehouses, which are the most suitable for their activities, or to adapt the existing warehouses to specifics of their activities. According to the existing or planned stock flows, required capacity and business processes we advise the sizes of warehouse zones (storage, packing, value-added services), recommend warehouse equipment and it’s mounting, what technologies should be used, amount and type of loading gates, which determines the size of a warehouse, design (columns grid), shape (open, U-type, one-way), traffic in the territory, etc. settings.

Our customers order these services often before the start of detailed design or even before the purchase of a land plot in order to have the baseline data, an opportunity to get business plan approved and to formulate a clear task for architects and designers.

With our help customers save both investment funds for the construction of a warehouse (avoid useless m2 and m3; the optimal layout of zones) and operating costs while working in them (heat losses, lighting, heating costs).

MORE ABOUT THE TECHNOLOGICAL DESIGN OF A WAREHOUSE LOGISTICS

Technological design of a warehouse logistics has to be taken into consideration before making the decision to build a new warehouse or reconstruct an existing one.

This is the central stage in the process of technical design, as the size, dimensions and shape of the warehouse largely depend on the technologies it is going to employ.

The drafting of a technological plan for the warehouse involves formulating its purpose, selecting the relevant type of spatial layout and shape, specifying the principal structures, assessing the throughput and recommending specific equipment and warehouse management systems. We present preliminary payback (ROI) spreadsheets to the investors.

All Lithuanians just must be basketball experts by nature. It is similar situation with the construction, including the construction of warehouses. There are those who think that the most important thing is to build warehouse with the biggest “cubic capacity” in order to stuff “everything”, and then they have to think how to work in here.

So, the design of internal warehouse processes is transferred to architects and designers, who usually have no understanding and experience of the warehouse processes and pay attention to the appearance and the construction cost. As a result, we can see “beautiful” warehouses, but inside – not-optimal width of the passage, pillars are in the middle of gathering area, or work process does not comply with the warehouse configuration (high free mileage or traffic “jams”).

Warehouses constructing companies should design the technological project of warehouse logistics first, in order to make optimum use of storage space and increase the efficiency of processes. It’s like a puzzle game – it will be difficult to understand the full picture until each folding part is analyzed and named. Components of such project are:

- description of individual warehouse processes;

- selection of goods storage and handling equipment;

- identification of spaces of warehouse premises;

- layout of the warehouse and the territory.

THE FOLLOWING TIPS WILL HELP TO AVOID TRAPS AND UNNECESSARY COSTS:

- Your business will change in the future, so when designing a warehouse, provide flexible possibilities for its transformation / adaptation.

- Take time and get acquainted with the theory of logistics in your field of business, global innovations, learn from the experience and discoveries of other companies.